First things first: The Precision 345 printer from Precision Label Products provides tremendous cost savings and versatility compared to pre-made pipe marking labels and other labeling systems.

Second things second: The friendly and helpful experts at Precision Label Products will make sure that you have everything you need to get the job done. They’ll also answer any questions you may have about our products, our shipping, our specially priced package deals, and the product and service support you get with each and every purchase.

Pipe marking projects require foresight, knowledge, and attention to detail. Consider even the most basic and yet essential of pipe markings (seen here in the photo): “Sprinkler Fire” in white text on a bright red background with unambiguous and unified directional arrows pointing rightward.

That message is clear as can be, and the materials are as durable as you will find anywhere, whether they’re applied indoors or outdoors, in extreme production facilities, or in places where they’re subjected to the ravages of time and relentless weather conditions.

And we make it easy to produce these essential pipe markings and materials on-site.

Whatever pipe marking materials you need, we are here to assist you throughout the process. So let us know how we can be of service!

Pipe Marking: Keep It Simple

Simplify your pipe marking project, expedite the process, and cut expenses tremendously by producing pipe marking labels on site with the Precision Label Products labeling system.

Print batches of chemical names and direction arrows fast and easy to greatly assist you in any size pipe marking project.

Pipe marking labels must effectively communicate the contents of all visible pipes and give additional detail if special hazards exist, such as extreme temperature or pressure.

Achieve successful pipe marking standards and results with confidence using products that comply with OHSA and ANSI/ASME A13.1 2015 Standards. (Quick note: ANSI is the American National Standards Institute; ASME is the American Society of Mechanical Engineers.)

* Fast and dependable, high-resolution label printing via the Precision Label Products 345 labeling system. (More on this remarkable printer below.)

* High-grade industrial indoor/outdoor weather and chemical resistant vinyl tape with an aggressive adhesive to ensure permanent adhesion to a variety of pipe and insulation surfaces.

* Top-grade chemically resistant ribbon to ensure label color contrast required by ANSI for maximum readability.

* Our black and white ribbons provide the highest quality contrast available.

Pipe Marking and Precision Label Products

Whether it’s an industrial plant, the utilities at an apartment complex, or anywhere else where a series of pipes or conduits are involved, pipe labeling is critical.

If there is any information that must be conveyed regarding the components of a facility’s infrastructure, pipe marking labels make it easy.

These markings are crucial in spaces where hazardous materials may be being transferred overhead or near heavy traffic areas where pipes may be bumped by pallet jacks, forklifts, or other equipment.

A burst pipe due to an accident is a lot more manageable if you know what you’re dealing with. Water is one thing; ammonia refrigeration is something else entirely.

Pipe Marking Requirements

In many fields, identification of pipe systems and other labeling requirements mean pipe marking is a necessity. While they don’t have any specific points to make about pipe marking, OSHA’s General Duty Clause states that every employer must provide for workplace safety. Additionally, OSHA (the Occupational Safety and Health Administration) does reference ANSI ASME a13.1 for many industries.

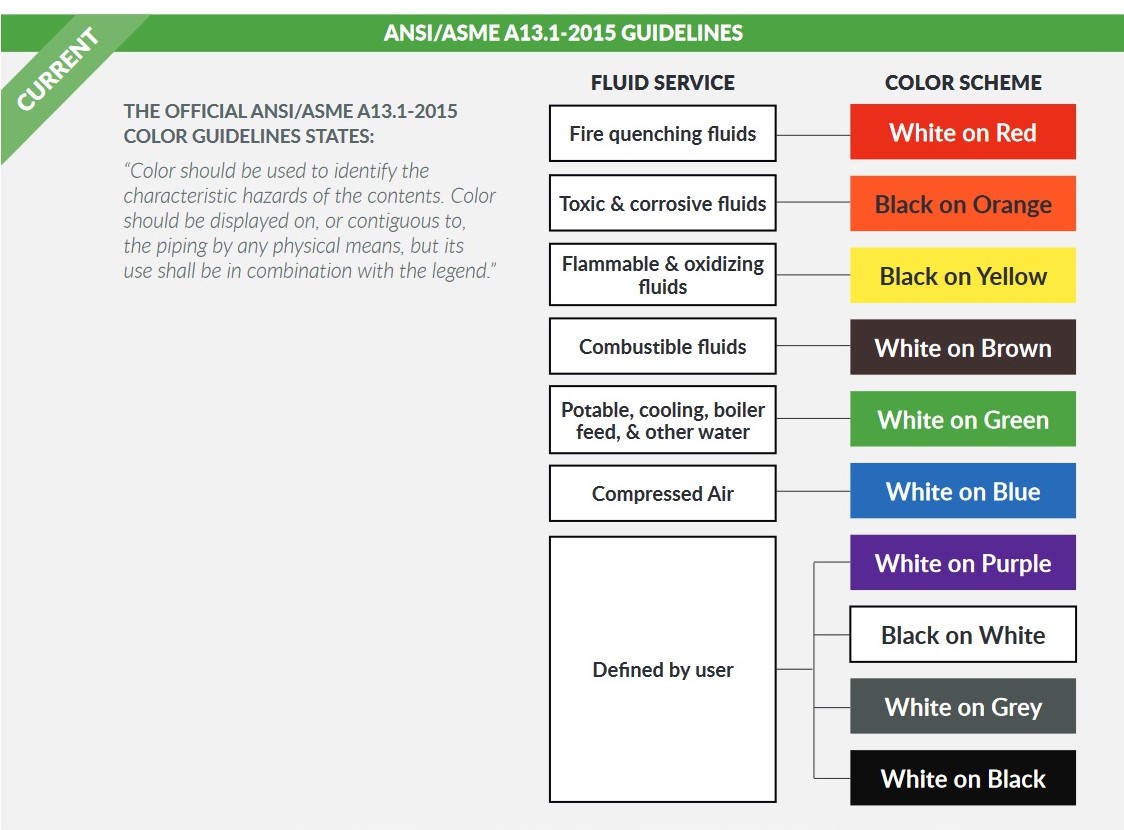

A feature of these pipe marker requirements includes color-coded markers to provide quick information on potentially hazardous leaks. For example, if pipe contents are toxic or corrosive, pipe markers are orange, while flammable or oxidizing materials are marked in yellow. These colors may also be found on other parts of the system, including valve tags.

Pipe markers can also be used to label specific pipe contents. A green pipe marker means “other water,” but facilities will print what that other water may be in white. Fire-quenching materials are marked in red, but also use white text to indicate precise materials. Black text is used on orange or black markers.

Other Uses of Pipe Marking

These markings, including arrows that define which way the materials are running, are all designed to make the workplace safer for its employees. Of course, not all facilities are carrying hazardous materials inside or outside of a building.

In addition to the standard colors used throughout the United States, there are also several user-defined colors for pipe markers. Purple, white, gray, and black are reserved for building managers to use as they see fit. For example, a hospital may use a white pipe marker to indicate a medical waste vacuum.

Easy Upgrades with Pipe Markings

Pipe markings also make any repairs or upgrades more efficient by clearly labeling what pipes do what.

Of course, before any updates are made, workers must have an understanding of how the system was first constructed and how they operate. That being said, pipe markers will make the job much easier.

Imagine dealing with a cluster of 14 of 15 pipes, each carrying a different material to different areas of the facility. With pipe markers, maintenance workers won’t constantly have to check and double-check which pipes need attention.

No matter what you’re using pipe markers for, contact Precision Label Products. In addition to tape, we also provide printers, thermal printer ribbon, die-cut labels, and other specialty labels for your business.

Precision 345 Desktop Thermal Transfer Printer

As promised, here’s some more information on the remarkable, steady, reliable, and durable Precision 345 Desktop Thermal Transfer Printer. It allows you to print your own custom vinyl, permanent adhesive labels.

In fact, the 345 series desktop thermal transfer printers offer speeds up to 5 inches per second (ips) with 300 dots per inch (dpi) resolution.

Find out some of the printer details.

* Standard memory: 4 MB FLASH, 8 MB SDRAM

* Comes with a slot for SD cards which expands FLASH storage to 4 GB.

* 32-bit microprocessor for fast printing and throughput.

* Serial, parallel, USB communication ports standard, as well as an on-board Ethernet LAN option for network installations.

* Command languages that can be flashed into the 345 printer include SPL II, TPLE, PLD, and TPLZ.

* Internal scalable True Type fonts using the Monotype® font engine.

* Easy to maintain. Printhead and platen (aka the flatbed; it’s the glass surface where papers, books, and other materials are placed for scanning) can be replaced in just seconds.

* User-friendly clamshell design

* Large, center-biased media capacity.

* Dual-Motor, gear-driven design provides horsepower capable enough to handle 984′ ribbons (more than three times longer than the industry standard for desktop label printers) and up to 150′ of vinyl tape.

* Two motors instead of one means lower torque, more durability, super quiet operation.

* Loading ribbons is a cinch.

* The ultimate compact industrial thermal transfer printer.

* One year full parts and labor warranty.

Here’s what you get when you purchase the 345 printer package:

* 345 printer

* Bartender Software and installation CDs

* Printed user guides, quick start guide, and USB installation guide

* USB cable

* Tape spindle, spindle tabs, ribbon spindles

You can download the 345’s technical specifications. Get in touch with Precision Label Products with any questions and to learn more about special pricing on orders.

You can always contact Precision Label Products anytime. We’re ready to work with you and answer questions you may have about the American Society of Mechanical Engineers (AMSE) technical data.

We’ve been in business since 2007. We are a veteran-owned and -operated company, and our focus is on providing our valued customers with the products and services they need at prices they’ll love!

In addition to our purchasing support, you’ll always have access to our friendly and helpful experts to answer any questions you have or to address any concerns you may have — whether it’s before, during, or after the sale.

For all your pipe marking and labeling needs, there’s no need to look any further. You’ll find everything you need right here at Precision Label Products.

ANSI Standard Color Codes

The ANSI standard has color codes for each classification of material. High-hazard materials require a yellow label with black letters. There are two color choices for low-hazard materials: green labels with white lettering if the low hazard material is liquid or liquid admixture, or blue with white lettering for gas or gaseous admixture. Fire suppression materials require red labels with white lettering.

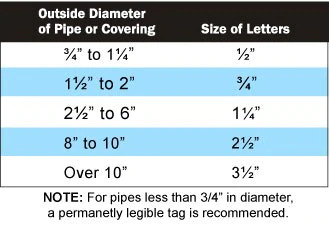

The ANSI standard also describes the size of label lettering relative to pipe diameter.

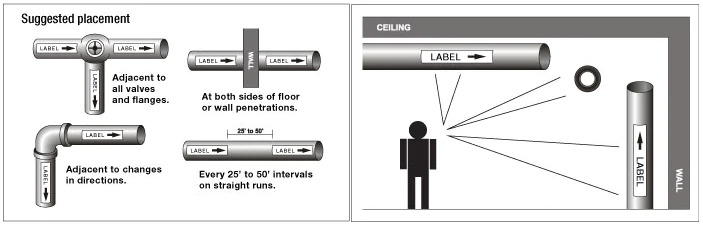

The ANSI standard describes how pipe identification labels should appear to be viewed properly. Positioning the labels depends on the pipe’s location in proximity to where it’s viewed. Labels should be placed on the bottom of overhead pipes and on the top of floor level pipes. Labels should be placed on the side of pipes viewed straight on. Labels should also be located near valves, branches, or where a change in direction occurs. Labels should be placed to mark the entry and re-entry points of pipes passing through walls. The key to pipe marking label placement is to have enough labels for easy identification.

Contact Precision Label Products for information regarding downloading American Society of Mechanical Engineers (AMSE) technical data.